Structures and Materials Research Laboratory

The laboratory provides research services for material testing in terms of the analysis of their composition, structure and properties. The laboratory tests materials from a wide range of materials science, including metals and their alloys, polymer materials and composites, ceramics, semiconductors and nanomaterials. The conducted analyses utilize electron microscopy and atomic force microscopy, X-ray diffraction, XPS spectroscopy, techniques related to the analysis of material properties related to physicochemical changes and research on materials degradation. The laboratory also conducts practical trainings and workshops in the field of applied techniques.

Contact: inquiries@port.lukasiewicz.gov.pl

X-ray Diffraction (XRD)

The qualitative and quantitative phase composition analysis with the X-rays utilization for solid powder crystalline samples with the possibility to determine the content of the amorphous phases. Phase transitions determination of crystalline samples within the temperature range between 12 and 290 K (PheniX Oxford) and 298 – 1473 K (HTK 1200N Anton Paar). Measurements of thin layers and epitaxial layers – reflection curves from symmetric and asymmetric planes, determining of the grid node maps reversed from the symmetric and asymmetric planes.

Atomic Force Microscopy (AFM)

Creating of surface maps in the nanoscale considering such properties as: friction, adhesion, elasticity, roughness, electrostatic charge distribution, electric conductivity, magnetic domain structure and thermal conductivity. Observation of progressing processes on the examined surface in real time, in the temperature range from -35 ˚C to 250 ˚C. Examining of surface topography (using available operation modes) of semiconductor samples, isolators, metallic and biological in diameter up to 210 mm and height 15 mm.

Testing of biological samples in their natural environment.

UHV measurements

Measurements under UHV conditions, allow quantitative and qualitative analyses concerning i.e. processes taking place on metal surfaces, semiconductors, isolators, powders and biological materials. In addition, the use of spectroscopic techniques (XPS, UPS, AES) allows to recognize the electron properties of tested surfaces. The methods such as LEED and STM, allow to obtain information of the surface atomic structure.

Scanning Electron Microscopy (SEM)

Automatic SEM analysis and identification of minerals, materials composition, phase and structure analysis at various size scale, including particles, deposits, dusts and soils. Evaluation of structure in terms of grain distributions, precipitates, inclusions and porosity. In-situ SEM observation of transformations upon sample heating up to 1400 °C. Imaging of semi-liquid and oily materials in SEM environmental mode. 3D imaging of structure and 3D mapping of composition. Composition and structure analysis of additives in composite and ceramic materials (e.g. polymer composites and construction ceramics). Characterization of post-production materials and semi-finished products. Verification of technological processes (e.g. quality of chemical etching, surface and structure evolution upon successive treatments).

FIB/SEM patterning of submicron structures and fabrication of mechanical (MEMS) and opto-mechanical components (MOEMS), fabrications of lamellas for TEM observations.

Transmission Electron Microscopy (TEM)

Atomic-level imaging and analysis of various types of materials. Sub-nanometric and atomic imaging, diffraction measurements, doping analysis, elemental EELS and EDX analysis. Wide usage in materials development. Measurements dedicated for device failure analysis, including multi-layer interfaces, quantum wells, dislocations, thin film / surface analysis and compositional mapping. Scanning mode (STEM) available in a combination with high angle annular dark field (HAADF) is strongly dependent on the average atomic number (Z-contrast) and it allows additional analyses were atomic resolution probe analyses are required.

Thermal analyses and polymer physicochemistry

Thermogravimetric analysis (TG), differential scanning calorimetry (DSC) equipped with high pressure (HP DSC) and ultra-fast heating calorimeter (Flash DSC) give information about the degradation of materials and the phase transitions processes. They are additionally supplemented with thermomechanical analysis (TMA) and dynamic mechanical analysis (DMA).

Simultaneous thermal analyser STA coupled with Fourier Transform Infrared Spectrometer (FTIR) and quadrupole mass spectrometer (QMS) enables measurements at the temperature up to 1650 °C. It is dedicated for physicochemical features analysis and allows to observe the thermal conductivity, thermal diffusivity, samples dimension changes during the dilatometric measurements and materials curing using dielectric analysis.

Porosity analyses

The porosity measurements are dedicated for powders and solids, including microporosity and mesoporosity tests (using physical adsorption of gases) and macroporosity (using mercury porosimetry), highly precise studies of chemical adsorption and temperature-programmed reactions to determine catalytic properties of the catalyst, catalyst supports or other materials.

Flammability tests

Flammability tests of polymers and plastics are performed for determination of the heat release, combustion of products, ignition time, flammability classification tests, getting from the burning process and optical density of smoke generated by materials.

Aging tests

The accelerated aging tests are achieved usingthermal resistance tests of materials and products (including thermal shock), salt spray corrosion tests containing variable cycles, exposure to high humidity and UV radiation.

X-ray Diffraction (XRD)

The qualitative and quantitative phase composition analysis with the X-rays utilization for solid powder crystalline samples with the possibility to determine the content of the amorphous phases. Phase transitions determination of crystalline samples within the temperature range between 12 and 290 K (PheniX Oxford) and 298 – 1473 K (HTK 1200N Anton Paar). Measurements of thin layers and epitaxial layers – reflection curves from symmetric and asymmetric planes, determining of the grid node maps reversed from the symmetric and asymmetric planes.

Atomic Force Microscopy (AFM)

Creating of surface maps in the nanoscale considering such properties as: friction, adhesion, elasticity, roughness, electrostatic charge distribution, electric conductivity, magnetic domain structure and thermal conductivity. Observation of progressing processes on the examined surface in real time, in the temperature range from -35 ˚C to 250 ˚C. Examining of surface topography (using available operation modes) of semiconductor samples, isolators, metallic and biological in diameter up to 210 mm and height 15 mm.

Testing of biological samples in their natural environment.

UHV measurements

Measurements under UHV conditions, allow quantitative and qualitative analyses concerning i.e. processes taking place on metal surfaces, semiconductors, isolators, powders and biological materials. In addition, the use of spectroscopic techniques (XPS, UPS, AES) allows to recognize the electron properties of tested surfaces. The methods such as LEED and STM, allow to obtain information of the surface atomic structure.

Scanning Electron Microscopy (SEM)

Automatic SEM analysis and identification of minerals, materials composition, phase and structure analysis at various size scale, including particles, deposits, dusts and soils. Evaluation of structure in terms of grain distributions, precipitates, inclusions and porosity. In-situ SEM observation of transformations upon sample heating up to 1400 °C. Imaging of semi-liquid and oily materials in SEM environmental mode. 3D imaging of structure and 3D mapping of composition. Composition and structure analysis of additives in composite and ceramic materials (e.g. polymer composites and construction ceramics). Characterization of post-production materials and semi-finished products. Verification of technological processes (e.g. quality of chemical etching, surface and structure evolution upon successive treatments).

FIB/SEM patterning of submicron structures and fabrication of mechanical (MEMS) and opto-mechanical components (MOEMS), fabrications of lamellas for TEM observations.

Transmission Electron Microscopy (TEM)

Atomic-level imaging and analysis of various types of materials. Sub-nanometric and atomic imaging, diffraction measurements, doping analysis, elemental EELS and EDX analysis. Wide usage in materials development. Measurements dedicated for device failure analysis, including multi-layer interfaces, quantum wells, dislocations, thin film / surface analysis and compositional mapping. Scanning mode (STEM) available in a combination with high angle annular dark field (HAADF) is strongly dependent on the average atomic number (Z-contrast) and it allows additional analyses were atomic resolution probe analyses are required.

Thermal analyses and polymer physicochemistry

Thermogravimetric analysis (TG), differential scanning calorimetry (DSC) equipped with high pressure (HP DSC) and ultra-fast heating calorimeter (Flash DSC) give information about the degradation of materials and the phase transitions processes. They are additionally supplemented with thermomechanical analysis (TMA) and dynamic mechanical analysis (DMA).

Simultaneous thermal analyser STA coupled with Fourier Transform Infrared Spectrometer (FTIR) and quadrupole mass spectrometer (QMS) enables measurements at the temperature up to 1650 °C. It is dedicated for physicochemical features analysis and allows to observe the thermal conductivity, thermal diffusivity, samples dimension changes during the dilatometric measurements and materials curing using dielectric analysis.

Porosity analyses

The porosity measurements are dedicated for powders and solids, including microporosity and mesoporosity tests (using physical adsorption of gases) and macroporosity (using mercury porosimetry), highly precise studies of chemical adsorption and temperature-programmed reactions to determine catalytic properties of the catalyst, catalyst supports or other materials.

Flammability tests

Flammability tests of polymers and plastics are performed for determination of the heat release, combustion of products, ignition time, flammability classification tests, getting from the burning process and optical density of smoke generated by materials.

Aging tests

The accelerated aging tests are achieved usingthermal resistance tests of materials and products (including thermal shock), salt spray corrosion tests containing variable cycles, exposure to high humidity and UV radiation.

SEM/FIB MICROSCOPE – FEI HELIOS NANOLAB 450HP

Scanning microscope with electron and ion columns, equipped with EDS detector. It allows general and high-resolution imaging, elemental analysis, three-dimensional data acquisition, and advanced transmission electron microscopy FIB samples preparation using Ga ions.

SEM MICROSCOPE – FEI QEMSCAN®650F

Scanning electron microscope for quantitative evaluation of minerals, equipped with set of two EDS XFlash detectors (Bruker Inc.) with an energy resolution of 133 eV. The QEMSCAN® system scans the electron beam over the sample area with the small micron-scale step size and acquires backscattered electron (BSE) signal and EDS X-ray intensity. The BSE SEM image provides material contrast due to its dependence on the atomic number, while EDS provides the local elemental composition. The final results, i.e., mineral or phase maps are obtained after processing the raw data by the iDiscover software which classifies a mineral by comparing EDS data at each pixel against a species identification protocol (SIP) database. It allows general and high-resolution imaging, elemental analysis, elemental maps acquisition, etc.

Scanning electron microscope for quantitative evaluation of minerals, equipped with set of two EDS XFlash detectors (Bruker Inc.) with an energy resolution of 133 eV. The QEMSCAN® system scans the electron beam over the sample area with the small micron-scale step size and acquires backscattered electron (BSE) signal and EDS X-ray intensity. The BSE SEM image provides material contrast due to its dependence on the atomic number, while EDS provides the local elemental composition. The final results, i.e., mineral or phase maps are obtained after processing the raw data by the iDiscover software which classifies a mineral by comparing EDS data at each pixel against a species identification protocol (SIP) database. It allows general and high-resolution imaging, elemental analysis, elemental maps acquisition, etc.

TEM MICROSCOPE – FEI TECNAI G2 X-TWIN

Transmission electron microscope with LaB6 gun for regular investigation of microstructure and its components with resolution of less than 0.25 nm. The instrument is fitted with EDS spectrometer for elemental analysis.

Transmission electron microscope with LaB6 gun for regular investigation of microstructure and its components with resolution of less than 0.25 nm. The instrument is fitted with EDS spectrometer for elemental analysis.

HR-S/TEM MICROSCOPE – FEI TITAN3 G2 60-300

Double Cs-corrected transmission electron microscope with high-brightness gun and high-sensitive EDS system for ultra-high-resolution structure examination and elemental analysis at the atomic level. The instrument is equipped with X-FEG gun, monochromator, two spherical aberration correctors (probe and image), four EDS detectors (ChemiSTEM), and operates at one of four accelerating voltages, i.e. 300, 200, 80 or 60 kV. It also allows 3D imaging with automated acquisition of tomography tilt series.

Double Cs-corrected transmission electron microscope with high-brightness gun and high-sensitive EDS system for ultra-high-resolution structure examination and elemental analysis at the atomic level. The instrument is equipped with X-FEG gun, monochromator, two spherical aberration correctors (probe and image), four EDS detectors (ChemiSTEM), and operates at one of four accelerating voltages, i.e. 300, 200, 80 or 60 kV. It also allows 3D imaging with automated acquisition of tomography tilt series.

X-ray diffractometer (Empyrean, PANalytical)

X-ray tubes Cu, Co and Ag, goniometer 240 mm in the vertical layout ensuring controlled lamp and detector movement with the resolution of 0.0001° and independent drive of angles θ and 2θ, range 2θ from – 110° to 168°,programmable primary optics with a set of apertures including a special aperture 1/32 Mo for low angle testing, Soller’s aperture 0.04°, 0.02° and 0.01°, double-reflection hybrid monochromator 2xGe (220), converging lenses for testing tension textures and in-plane, Bragg-Brentano’s optics unit including programmable receiving apertures and fixed anti-dispersion apertures, triple axis module with the analysing crystal for high resolution testing, point scintillation deflector and semiconductor PIXcel3D mounted on a single double arm. The system is also equipped with high temperature attachment Anton Paar HTK1200N and low temperature attachment Oxford Cryosystems PheniX. The reference samples are dedicated for the following measurements: SAXS, tensions, texture, reflectometry, epitaxial layers, patterns (NIST: LaB6, Al2O3, Si, ZnO, TiO2, Cr2O3, CeO2,).

X-ray tubes Cu, Co and Ag, goniometer 240 mm in the vertical layout ensuring controlled lamp and detector movement with the resolution of 0.0001° and independent drive of angles θ and 2θ, range 2θ from – 110° to 168°,programmable primary optics with a set of apertures including a special aperture 1/32 Mo for low angle testing, Soller’s aperture 0.04°, 0.02° and 0.01°, double-reflection hybrid monochromator 2xGe (220), converging lenses for testing tension textures and in-plane, Bragg-Brentano’s optics unit including programmable receiving apertures and fixed anti-dispersion apertures, triple axis module with the analysing crystal for high resolution testing, point scintillation deflector and semiconductor PIXcel3D mounted on a single double arm. The system is also equipped with high temperature attachment Anton Paar HTK1200N and low temperature attachment Oxford Cryosystems PheniX. The reference samples are dedicated for the following measurements: SAXS, tensions, texture, reflectometry, epitaxial layers, patterns (NIST: LaB6, Al2O3, Si, ZnO, TiO2, Cr2O3, CeO2,).

Atomic force microscope(Dimension FastScan, Bruker)

It enables rapid scanning in the range up to 35μm in the XY axis and to ≤ 3μm in the axe Z, it works in a closed loop of loopback and features thermally compensated tensometric sensors. As a standard it serves the following operation modes: Peak Force Tapping / Scan Asyst (in the air or in liquids), Tapping Mode (in the air or in liquids), Phase Imaging, Contact Mode, Lateral Force Microscopy, Magnetic Force Microscopy (MFM), Electrostatic Force Microscopy (EFM).

It enables rapid scanning in the range up to 35μm in the XY axis and to ≤ 3μm in the axe Z, it works in a closed loop of loopback and features thermally compensated tensometric sensors. As a standard it serves the following operation modes: Peak Force Tapping / Scan Asyst (in the air or in liquids), Tapping Mode (in the air or in liquids), Phase Imaging, Contact Mode, Lateral Force Microscopy, Magnetic Force Microscopy (MFM), Electrostatic Force Microscopy (EFM).

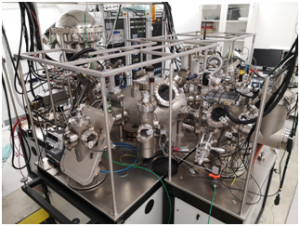

Ultra-High-vacuum system (PREVAC)

UHV system is equipped with analytical and preparatory chambers, scanning tunneling microscope, high pressure reactor. The pressure inside of the chambers is 5·10-11 Torr. Measurements can be performed from helium temperatures to over 200 °C. The analytical chamber is provided with a hemispheric analyser VG SCIENTA with a monochromator, it allows testing of surface electron structure using XPS, AES, UPS and ARPES.

UHV system is equipped with analytical and preparatory chambers, scanning tunneling microscope, high pressure reactor. The pressure inside of the chambers is 5·10-11 Torr. Measurements can be performed from helium temperatures to over 200 °C. The analytical chamber is provided with a hemispheric analyser VG SCIENTA with a monochromator, it allows testing of surface electron structure using XPS, AES, UPS and ARPES.

Thermal analyzers

The laboratory is equipped with different thermal based analyzers, namely:

- Differential scanning calorimeter with modulated temperature MT-DSC (Mettler-Toledo DSC1)

- Differential scanning calorimeter Flash-DSC (Mettler-Toledo Flash DSC1)

- Differential scanning calorimeter High-Pressure-DSC (Mettler Toledo HP DSC1)

Thermogravimetric analyzer TG (Mettler Toledo TGA2) - Dynamic mechanical analyzer DMA (Mettler Toledo DMA/SDTA 861)

- Thermomechanical analyzer TMA (Mettler Toledo TMA/SDTA1 LN 600 i TMA/SDTA 1 LF 1100)

- Thermal analyzer (TG-DSC/DTA) coupledtoQMS and IR with ATR (Netzsch STA 449 F1 Jupiter; Bruker FTIR Tensor 27; QMS Aeolos)

- High temperature dilatometer DIL (Netzsch DIL 402C)

- Thermal diffusivity analyzer LFA (Netzsch LFA 457 MicroFlash)

- Thermal conductivity analyzer HFM (Netzsch HFM 436 Lambda)

- Dielectric analyzer DEA (Netzsch DEA 288 Epsilon)

Porosimeters

The laboratory is able to perform physical sorption analyses using 3Flex (e.g. low-temperature nitrogen adsorption), mercury porosimeter AutoPore IV 9510, chemical sorption analyzer AutoChem, helium pycnometer for density measurements AccuPyc 1340

Flammability analyzers

The following flammability measurements are available: smoke density using chamber NBS SDC, elevated temperature oxygen index tests, horizontal/vertical flame chamber according to UL94, cone calorimeter CONE O2/CO2/CO

- Cone calorimeter (FTT CONE O2/CO2/CO)

- Smoke density chamber (FTT NBS SDC)

- Temperature and oxygen index apparatus (FTT OI+TOI)

- Plastic flammability testing apparatus UL94 (FTT UL 94)

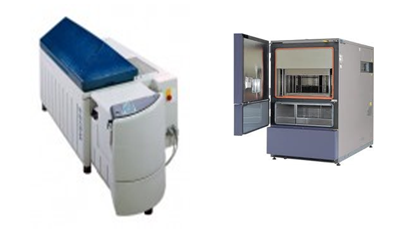

Aging chambers

Aging chambers: accelerated weathering tester QUV Spray, thermal shock chamber TS60, temperature and climate test chamber WK3 340/70, salt spray test chamber WSC KWT450/SO2

- UV accelerated aging chamber (Q- LAB QUV Spray)

- Thermal shock chamber (WEISS TS 60)

- Climatic chamber (WEISS WK3 340/70)

- Salt fog chamber (WEISS S.C. KWT 450/SO2)

The laboratory also includes more than 30 devices and accessories for conventional samples preparation.

- POLONEZ 1, NCN, „Atomic scale study of emerging UV-light LEDs by advanced transmission electron microscopy”, 2017-2018.

- POIR, NCBR, “Manufacturing of graphene layers on copper connections for electronic applications”, 2019-2022.

- GRIEG, NCN, “2D MXenes based anode materials for all-solid-state Li-ion batteries”, 2020-2023.